Let's Talk

Water flushes through the shaft and helps remove deposits from tube. Forward direction foot switch enables operator to concentrate on cleaning operation without worrying about cleaner. Flexible shaft can be easily disconnected. Stainless steel body for use in the harshest environments. Easy interchangeability of various shafts and accessories for maximum versatility. Large wheels for easy transportation. Water consumption can be regulated as needed.

| Tube I.D. |

Tube Cleaner Model No. |

Motor Power |

Motor Speed RPM |

Weight | Dimension | |||||

| mm | inch | HP | KW | High | Kg. | Wide | Deep | Kg. | ||

| 6.4-25.4 | 1/4-1 | PTC-40 | 1/2 | 0.4 | 890 | 62 | 28 | 38″(975mm) | 21″(535mm) | 18″(457mm) |

| 6.4-25.4 | 1/4-1 | PTC-60 | 3/4 | 0.6 | 890 | 66 | 30 | 38″(975mm) | 21″(535mm) | 18″(457mm) |

| 25.4 & UP | 1 & UP | PTC-75 | 1 | 0.75 | 1780 | 70 | 32 | 38″(975mm) | 21″(535mm) | 18″(457mm) |

| 25.4 & UP | 1 & UP | PTC-150 | 2 | 1.5 | 1780 | 84 | 38 | 40″(1015mm) | 22″(560mm) | 19″(482mm) |

Compact and portable for use in multiple locations. Easy connect and disconnect of various shafts and cleaning tools. Foot Switch enables operator to concentrate on cleaning operation. Water moving through shaft flushes out deposits already dislodged by cleaning tools.

| Tube I.D. |

Tube Cleaner Model No. |

Motor Power |

Motor Speed RPM |

Weight | Dimension | |||||

| mm | inch | HP | kW | High | Kg. | Wide | Deep | Kg. | ||

| 6.4-25.4 | 1/4-1 | PORTO | 1/2 | 0.4 | 1760 | 36 | 16 | 10″(254mm) | 11″(279mm) | 18″(457mm) |

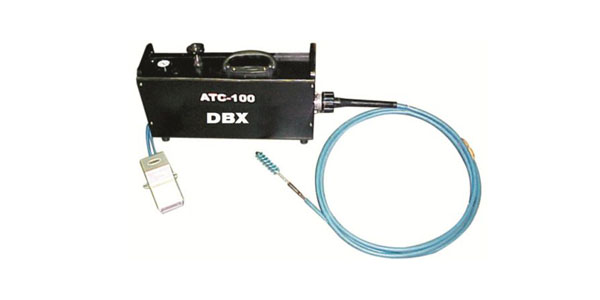

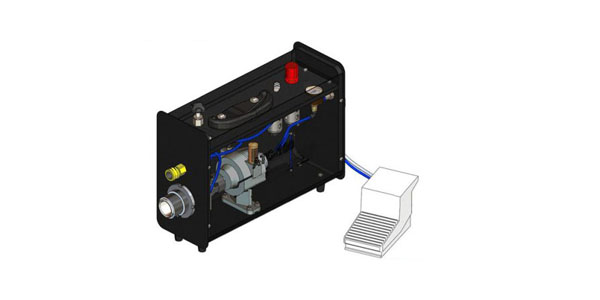

Shock Resistant – Excellent for applications where using electric equipment is hazardous. Corrosion Resistant – Stainless steel cover and chassis for long life. Versatile – Interchangeability of different size flexible shafts and cleaning tools. Speed/Torque control – Shaft rotation can be set at optimum speed for each application.

| Tube I.D. |

Tube Cleaner Model No. |

Motor Power |

Motor Speed RPM |

Weight | Dimension | |||||

| mm | inch | HP | kW | High | Kg. | Wide | Deep | Kg. | ||

| 6.4 & UP | 1/4 & UP | ATC-300 | 4 | 3 | 300-3000 | 64 | 29 | 38”(975mm) | 22”(560mm) | 16”(406mm) |

Shock Resistant – Excellent for applications where use of electric equipment is hazardous. Versatile – Interchangeability of different size flexible shafts and cleaning tools. Speed/Torque control – Shaft rotation speed can be set at optimum for each application. No Tooling – Quick disconnection of flexible shaft. Time Saving – Simultaneous water flush to remove deposits from tubes. Cleanliness – Foot switch for operator’s convenience to activate both shaft rotation and water flow to reduce water consumption and making working area clean. Compact – Light weight easy to operate inside drum.

| Tube I.D. |

Tube Cleaner Model No. |

Motor Power |

Motor Speed RPM |

Air | Supply | Weight | Dimension | |||||

| mm | inch | HP | kW | Min | Max | lbs. | Kg. | High | Wide | Deep | ||

| 6.4 & UP | 1/4 & UP | ATC-100 | 1.7 | 1.1 | 300-3000 | 60psi @ 15cfm | 100psi @ 70cfm | 26 | 12 | 10.3/8”(655mm) | 6”(152mm) | 19”(483mm) |

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

| Model No. | Motor H.P. | Speed (RPM) | Electric Supply |

| TC-30 | 3 | – | 440V |

| TC-50 | 5 | 2800 | 3 PHASE |

| TC-75 | 7.5 | – | 50 Hz |

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

| Size |

TH’ Turk Head Brush Model No. |

‘DS’ Double Spiral Brush Model No |

‘WBA’ Brush Model No |

‘EXP’ Expanding Brush Model No. |

‘MB’ Multi Purpose Brush Model No. |

‘CB’ Circular Wheel Brush Model No. |

‘CB’ Circular Wheel Brush Model No. |

‘EXS’ Expanding Scrapers Model No. |

|

| mm | inch | ||||||||

| 31.7 | 1.1/4 | TH-10 | DS-10 | WBA-10 | EXP-10 | MB-10 | CB-10 | – | EXS-10 |

| 35 | 1.3/8 | TH-11 | DS-11 | WBA-11 | EXP-11 | MB-11 | CB-11 | – | EXS-11 |

| 38.1 | 1.1/2 | TH-12 | DS-12 | WBA-12 | EXP-12 | MB-12 | CB-12 | – | EXS-12 |

| 41.3 | 1.5/8 | TH-13 | DS-13 | WBA-13 | EXP-13 | MB-13 | CB-13 | – | EXS-13 |

| 44.5 | 1.3/4 | TH-14 | DS-14 | WBA-14 | EXP-14 | MB-14 | CB-14 | – | EXS-14 |

| 47.6 | 1.7/8 | TH-15 | DS-15 | WBA-15 | EXP-15 | MB-15 | CB-15 | – | EXS-15 |

| 50.8 | 2 | TH-16 | DS-16 | WBA-16 | EXP-16 | MB-16 | CB-16 | RS-16 | EXS-16 |

| 54 | 2.1/8 | TH-17 | DS-17 | WBA-17 | EXP-17 | MB-17 | CB-17 | RS-17 | EXS-17 |

| 57.1 | 2.1/4 | TH-18 | DS-18 | WBA-18 | EXP-18 | MB-18 | CB-18 | RS-18 | EXS-18 |

| 60.3 | 2.3/8 | TH-19 | DS-19 | WBA-19 | EXP-19 | MB-19 | CB-19 | RS-19 | EXS-19 |

| 60.3 | 2.3/8 | TH-19 | DS-19 | WBA-19 | EXP-19 | MB-19 | CB-19 | RS-19 | EXS-19 |

| 63.5 | 2.1/2 | TH-20 | DS-20 | WBA-20 | EXP-20 | MB-20 | CB-20 | RS-20 | EXS-20 |

| 66.7 | 2.5/8 | TH-21 | DS-21 | WBA-21 | EXP-21 | MB-21 | CB-21 | RS-21 | EXS-21 |

| 70 | 2.3/4 | TH-22 | DS-22 | WBA-22 | EXP-22 | MB-22 | CB-22 | RS-22 | EXS-22 |

| 73 | 2.7/8 | TH-23 | DS-23 | WBA-23 | EXP-23 | MB-23 | CB-23 | RS-23 | EXS-23 |

| 76.2 | 3 | TH-24 | DS-24 | WBA-24 | EXP-24 | MB-24 | CB-24 | RS-24 | EXS-24 |

| 79.4 | 3.1/8 | TH-25 | DS-25 | WBA-25 | EXP-25 | MB-25 | CB-25 | RS-25 | EXS-25 |

| 82.5 | 3.1/4 | TH-26 | DS-26 | WBA-26 | EXP-26 | MB-26 | CB-26 | RS-26 | EXS-26 |

| 85.7 | 3.3/8 | TH-27 | DS-27 | WBA-27 | EXP-27 | MB-27 | CB-27 | RS-27 | EXS-27 |

| 88.9 | 3.1/2 | TH-28 | DS-28 | WBA-28 | EXP-28 | MB-28 | CB-28 | RS-28 | EXS-28 |

| 92.1 | 3.5/8 | TH-29 | DS-29 | WBA-29 | EXP-29 | MB-29 | CB-29 | RS-29 | EXS-29 |

| 95.2 | 3.3/4 | TH-30 | DS-30 | WBA-30 | EXP-30 | MB-30 | CB-30 | RS-30 | EXS-30 |

| 98.4 | 3.7/8 | TH-31 | DS-31 | WBA-31 | EXP-31 | MB-31 | CB-31 | RS-31 | EXS-31 |

| 101.6 | 4 | TH-32 | DS-32 | WBA-32 | EXP-32 | MB-32 | CB-32 | RS-32 | EXS-32 |

For Tubes/Pipes 1.1/4″-4″ (31.7mm-101.6mm) I.D. These Cutter Heads are designed for cleaning straight and curved tubes as found in Boilers, Air Heaters, Economizers, etc. Cutter Heads are provided with 3 cutter wheels, one each of straight teeth, teeth cut right hand, teeth cut left hand, for quicker cleaning and prevention of scale grooving.

|

Model No |

Tube I.D | Cutter Wheels Model Set (3) | Spare Spindle | |

| mm | inches | Model No. | Model No. | |

| H-10 | 31.7 | 1.1/4 | HSRL-1 | HA-1 |

| H-11 | 35 | 1.3/8 | HSRL-1 | HA-1 |

| H-12 | 38.1 | 1.1/2 | HSRL-1 | HA-1 |

| H-12 | 41.3 | 1.5/8 | HSRL-2 | HA-2 |

| H-13 | 44.5 | 1.3/4 | HSRL-2 | HA-2 |

| H-15 | 47.6 | 1.7/8 | HSRL-2 | HA-2 |

| H-16 | 51 | 2 | HSRL-2 | HA-2 |

| H-17 | 54 | 2.1/8 | HSRL-2 | HA-2 |

| H-18 | 57.1 | 2.1/4 | HSRL-3 | HA-3 |

| H-20 | 63.5 | 2.1/2 | HSRL-3 | HA-3 |

| H-22 | 70 | 2.3/4 | HSRL-4 | HA-3 |

| H-24 | 76.2 | 3 | HSRL-4 | HA-3 |

| H-26 | 82.5 | 3.1/4 | HSRL-5 | HA-3 |

| H-28 | 88.9 | 3.1/2 | HSRL-5 | HA-3 |

| H-30 | 95.2 | 3.3/4 | HSRL-6 | HA-4 |

| H-32 | 101.6 | 4 | HSRL-6 | HA-4 |

|

Model No |

Tube I.D | Cutter Wheels Model Set (15) | Spare Arms | |

| mm | inchs | Model No. | Model No. | |

| HZ-10 | 31.7 | 1.1/4 | HZSRL-1 | HZA-1 |

| HZ-10A | 33.3 | 1.5/16 | HZSRL-1 | HZA-1 |

| HZ-11 | 35 | 1.3/8 | HZSRL-1 | HZA-1 |

| HZ-11A | 36.5 | 1.7/16 | HZSRL-1 | HZA-2 |

| HZ-12 | 38.1 | 1.1/2 | HZSRL-1 | HZA-2 |

| HZ-12A | 39.7 | 1.9/16 | HZSRL-1 | HZA-2 |

| HZ-13 | 41.3 | 1.5/8 | HZSRL-1 | HZA-2 |

| HZ-13A | 42.9 | 1.11/16 | HZSRL-1 | HZA-2 |

| HZ-14 | 44.5 | 1.3/4 | HZSRL-2 | HZA-3 |

| HZ-14A | 46 | 1.13/16 | HZSRL-2 | HZA-3 |

| HZ-15 | 47.6 | 1.7/8 | HZSRL-2 | HZA-3 |

| HZ-15A | 49.2 | 1.15/16 | HZSRL-2 | HZA-3 |

| HZ-16 | 51 | 2 | HZSRL-2 | HZA-3 |

Inner Core is double wound in opposing layers made out of high tensile-spring steel wires and passed through stress relieving process, made to absolute-vibration free performance and continuous duty.

Outer Casing is flexible, made out of galvanized steel strip and provided with special steel anti-friction lining for the entire length.

Suitable motor connection at one end and detachable ball bearing hand piece (tool holder) with threaded spindle for tool head or brush at other end. The size of the flexible shaft is based on internal diameter (I.D.) of the tube. The length of flexible shaft required is the addition of the length of the longest tube plus the distance between the mouth of the tube and the position of the power unit. The power unit should be located so that the flexible shaft be kept as straight as possible.

| Inner Core mm (inch) | 12 – 13 (1/2”) | 15 – 16 (5/8”) | 19 – 20 (3/4”) | |

| Outer Casing mm (inch) | 25 – 26 (1”) | 31 – 32 (1.1/4”) | 34 – 35 (1.3/8”) | |

| Length | – | – | – | |

| mm | inch | Model No. | Model No. | Model No. |

| 7.5 | 25 | IFS-105-25 | IFS-106-25 | IFS-106-25 |

| 9 | 30 | IFS-105-30 | IFS-106-30 | IFS-106-30 |

| 10 | 33 | IFS-105-33 | IFS-106-33 | IFS-106-33 |

| 12 | 40 | IFS-105-40 | IFS-106-40 | IFS-106-40 |

| 15 | 50 | IFS-105-50 | IFS-106-50 | IFS-106-50 |

| 18 | 60 | IFS-105-60 | IFS-106-60 | IFS-106-60 |

| 20 | 65 | IFS-105-65 | IFS-106-65 | IFS-106-65 |

| Spare Inner Core Per mtr. | IC-105 | IC-106 | IC-107 | |

| Spare Outer Casing Per mtr. | OC-105 | OC-106 | OC-107 | |

| Spare Hand Piece. | HP-105 | HP-106 | HP-107 | |

| Inner Core mm (inch) | 12 – 13 (1/2”) | 15 – 16 (5/8”) | 19 – 20 (3/4”) | |

| Outer Casing mm (inch) | 25 – 26 (1”) | 31 – 32 (1.1/4”) | 34 – 35 (1.3/8”) | |

| Length | – | – | – | |

| mm | inch | Model No. | Model No. | Model No. |

| 7.5 | 25 | IFS-105-25 | IFS-106-25 | IFS-106-25 |

| 9 | 30 | IFS-105-30 | IFS-106-30 | IFS-106-30 |

| 10 | 33 | IFS-105-33 | IFS-106-33 | IFS-106-33 |

| 12 | 40 | IFS-105-40 | IFS-106-40 | IFS-106-40 |

| 15 | 50 | IFS-105-50 | IFS-106-50 | IFS-106-50 |

| 18 | 60 | IFS-105-60 | IFS-106-60 | IFS-106-60 |

| 20 | 65 | IFS-105-65 | IFS-106-65 | IFS-106-65 |

| Spare Inner Core Per mtr. | IC-105 | IC-106 | IC-107 | |

| Spare Outer Casing Per mtr. | OC-105 | OC-106 | OC-107 | |

| Spare Hand Piece. | HP-105 | HP-106 | HP-107 | |

The portable pneumatic tube cleaners use hollow shafting of different diameters as per tube I.D. to be cleaned which can be coupled together to form lengths as per the length of the tube to be cleaned. Water flows through the hollow tube and washes out deposits that are dislodged by the cleaning tools attached to the driven shafts. Typical cleaning tools used are carbide drills for severely clogged tubes, brushes for light deposits and buffing tools for fin al polishing of tubes. The water flow is independently controlled allowing the user to determine how much water is needed in the application.

| Tube I.D.’s suited for | Model No. | Max Motor Power |

Free Speed RPM |

Air Supply | Water Supply | Weight | |||||

| mm | inch | HP | KW | Min | Max | Min | Max | lbs. | Kg. | ||

| 4.8-25.4 | 3/16-1 | C-10 | 0.6 | 0.45 | 700 | 60psi@16cfm | 90psi@16cfm | 30psi | 100psi | 5.72 | 2.6 |

| 6.4-25.4 | 1/4-1 | PTC-60 | 3/4 | 0.6 | 1000 | 90psi@20cfm | 90psi@40cfm | 30psi | 100psi | 6.6 | 3 |

4ft. (1.2m) long aircraft quality steel shafts to connect to driven shafts. Order quantities based on length of tube to be cleaned.

Model: DC-300 to DC-500

Model: DC-562 to DC-750

4ft. (1.2m) long aircraft quality steel shafts to connect to driven shafts. Order quantities based on length of tube to be cleaned.

Model: DN-300 to DN-500

Model: DN-562 to DN-750

To Couple hollow drive shaft to drive.

Model: DS-300 to DS-500

Model: DS-562 to DS-750

To Couple 2 hollow shafts together.

Model: SC-300 to SC-500

Model: SC-562 to SC-750

To Couple 2 hollow shafts together.

Model: SD-300 to SD-500

Model: DS-562 to SD-750

| Tube I.D.’s suited for | Drive Model No. | Hollow Drive Shaft Model No. | Hollow Driven Shaft Model No. | Drive Coupling Model No. | Shaft Coupling Model No. | Starter Drill Model No. | |

| mm | inch | – | – | – | – | – | – |

| 4.8-6.4 | 3/16-1/4 | C-10 | DS-300 | DN-300 | DC-300 | SC-300 | – |

| 9.5 | 3/8 | – | DS-312 | DN-312 | DC-312 | SC-312 | SD-312 |

| 11.1 | 7/16 | – | DS-375 | DN-375 | DC-375 | SC-375 | SD-375 |

| 12.7-14.3 | 1/2-9/16 | – | DS-437 | DN-437 | DC-437 | SC-437 | SD-437 |

| 15.9-17.5 | 5/8-11/16 | DS-500 | DN-500 | DC-500 | SC-500 | SD-500 | |

| 19.1-20.6 | 3/4-13/16 | – | DS-562 | DN-562 | DC-562 | SC-562 | SD-562 |

| 22.2-25.4 | 7/8-1 | CP-315 | DS-625 | DN-625 | DC-625 | SC-625 | SD-625 |

| 27.0-51.0 | 1.1/16-2 | DS-750 | DN-750 | DC-750 | SC-750 | SD-750 | |

C-101, 1st Floor,Jainam Arcade, Bhaichand Textile Mills Compound, L.B.S. Marg, Bhandup (W). Mumbai 400078, Maharashtra, India.